Turning Used Plastic Containers into Playgrounds for Children

.png)

The growing emphasis on using recycled plastic is more than just a trend. It’s the future for smart, sustainable business in any field or industry. Using recycled playground equipment is the simplest way to provide eco-friendly entertainment to the children of your community.

Procuring Raw Materials

Contrary to what you may believe, all plastics are not created equal. High-density polyethylene (HDPE) is classified as #2 plastic and most often used for recycled plastic playground equipment. Plastic containers, such as milk jugs, are some of the most common HDPE products recycled and repurposed for playground materials.

This type of plastic is ideal because it maintains constitution through a wide range of climates and meets the standard requirements for LEED certification. We know not everyone has luxury of recycling pickup services, but you can learn how to recycle locally by entering your zip code at iwanttoberecycled.org.

Remember, providing the raw materials is the first and most important step in sustainable construction processes.

Molding and Assembly

Recycled plastic posts are produced through a unique and fascinating process. Once milk jugs (or whichever HDPE product is being recycled) have been cleaned and flattened, the materials are sent through shredding machines that break the plastic down into smaller particles.

Those particles are then heated to bond with a coloring agent that produce plastic play equipment that retains the same color throughout. There are a number of methods used to shape plastic into desired structures. Learn more here.

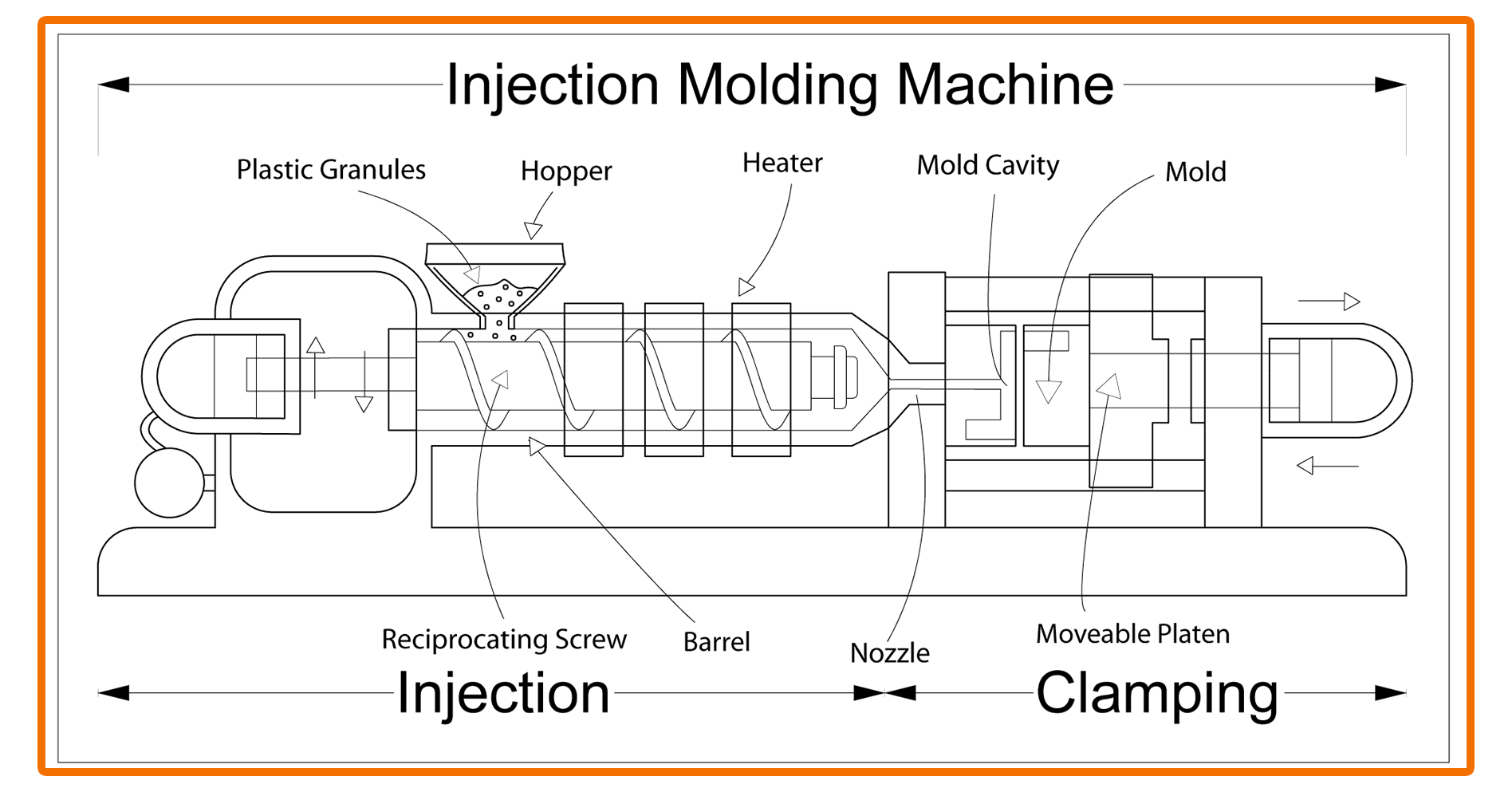

The most common method for assembling recycled plastic structures is injection molding. The machine extrudes the recycled plastic into specific post sizes that are cut and sorted. Once the material is cut to size, the end products are assembled to make components such as decks, bridges, roofs, or outdoor furniture.

While this production process is quick, high demand of the raw material has driven up the cost. Luckily, this is where your spare milk jugs and used playground equipment might come to the rescue.

Milk Jugs for Playgrounds

Here’s the best news yet. You can donate plastic jugs toward a great cause! If your used commercial playground equipment is made of HDPE plastic, you can recycle that too! Remember that a small bench will use around 500 milk jugs. A larger playground structure can use over 70,000 jugs. Donations of jugs must be thoroughly cleaned, pressed, and delivered to the factory.

The result of your effort is a recycled plastic playground that will not rust, splinter, peel, or crack. At the same time, you’ll be saving landfill space and doing your part in sustaining the environment and community in which you live.

And who knows? including a green component in your playground initiative may help you score a little extra funding in the planning phases.